Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Cutting hardwood can be challenging. It’s not just about having a powerful chainsaw; it’s about using the right tools. The key to success lies in choosing the right chainsaw chain.

In this article, we’ll explore why the right chainsaw chain matters more than power. You’ll learn how selecting the correct chain can make your hardwood cutting more efficient, safer, and easier.

Hardwoods like oak, hickory, and maple are much tougher than softwoods. Their dense fibers resist fast cutting, requiring more force and time to slice through them. When using the wrong chainsaw chain, this resistance can cause excessive wear on the chain and make the job longer and more difficult. Unlike softer woods, hardwoods need a more durable and efficient cutting tool that can handle the challenge.

Hardwoods often contain moisture, sap, and dirt. These factors not only dull your chainsaw chain quickly but can also clog it, making the cutting process inefficient. Additionally, some hardwoods contain hidden debris like nails or gravel, especially when cutting reclaimed wood or old stumps. These elements can damage the chain and increase the frequency of required maintenance.

When a chainsaw chain dulls, it causes erratic cuts that may be unsafe for the user. A dull chain requires more pressure, increasing the likelihood of kickback, where the saw jerks backward unexpectedly. This is dangerous for the operator, especially when cutting dense hardwood. Choosing the right chainsaw chain for the job can significantly reduce this risk.

Full chisel chains are known for their aggressive cutting ability. They are designed to cut quickly through clean, dry hardwood, making them perfect for fast jobs in ideal conditions. However, full chisel chains wear out faster, especially when cutting through moist or dirty wood, making them less durable in harsher conditions.

Semi-chisel chainsaw chains strike a balance between cutting speed and durability. They are slower than full chisel chains but remain sharper for longer periods, especially when cutting through hardwood that contains dirt, sap, or moisture. This type of chain is well-suited for people who need reliability and extended cutting performance in various conditions.

Carbide-tipped chains are specifically designed for extreme cutting conditions. With industrial-grade carbide tips, these chains offer exceptional edge retention, often lasting up to 25 times longer than steel chains. These chains can handle the toughest hardwood cutting tasks, including cutting through dirt, frozen wood, and debris. If you're working in challenging environments or have a high-volume cutting job, carbide-tipped chains are the ideal choice.

When selecting a chainsaw chain, two critical specifications to consider are pitch and gauge. The pitch refers to the distance between the links on the chain, and the gauge refers to the thickness of the drive links. Both of these specifications must match your chainsaw bar to ensure proper function. Choosing the wrong pitch or gauge can cause the chain to bind, wear out more quickly, or even damage your saw bar.

Specification | Description | Common Sizes |

Pitch | Distance between drive links | 3/8", .325", .404" |

Gauge | Thickness of the drive links | .050", .063" |

Tip: Always check your chainsaw manual to ensure the right pitch and gauge before purchasing a new chain.

The cutter profile of the chainsaw chain affects cutting performance. Full chisel chains are known for their speed, especially on clean, dry wood, but they wear down faster. Semi-chisel chains have rounded edges and provide a more durable cutting option, especially for dirty or tough conditions. Chamfer cutters are designed to resist impact and perform well in a variety of cutting environments, including hardwood and debris-filled conditions.

Cutter Profile | Characteristics | Best Use Case |

Full Chisel | Sharp, square edges, fast cuts | Clean, dry hardwood |

Semi-Chisel | Rounded edges, more durable, slower cuts | General hardwood cutting, wet wood |

Chamfer | Rounded corners, impact-resistant | Cutting through dirty or frozen wood |

Note: Choosing the right cutter profile depends on the wood you're cutting and the environmental conditions.

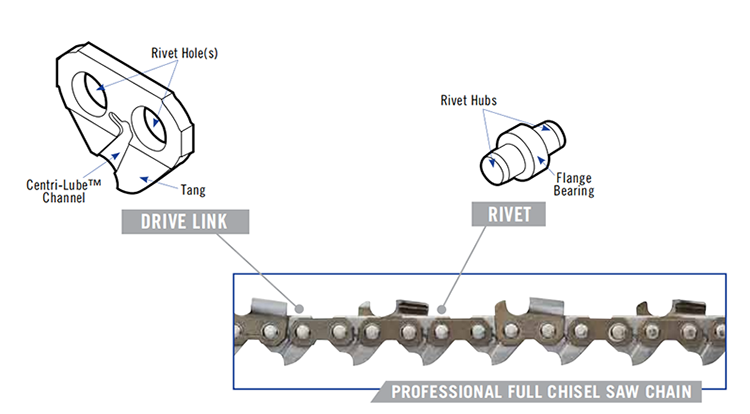

Drive links refer to the teeth on the chainsaw chain that engage with the saw bar. The number of drive links determines the chain length, and it is essential to match this with your saw's bar length. Using a chain with too few or too many drive links can lead to poor performance or damage to your chainsaw.

Regular sharpening is essential for maintaining the cutting efficiency of your chainsaw chain. A dull chain not only cuts slower but also increases the risk of accidents and strain on your chainsaw. Always ensure that the teeth are sharp and even, and use proper sharpening tools to maintain the chain’s performance.

Tip: Sharpen your chain every time you notice a reduction in cutting speed or when the chain starts leaving sawdust instead of clean wood chips.

Proper chain tensioning ensures that the chain remains taut during cutting, reducing wear and preventing damage. Lubricating the chain with the correct oil is equally important to ensure smooth operation. Lack of lubrication can cause excessive friction, wearing down both the chain and the bar.

Maintenance Task | Importance | How Often to Perform |

Sharpening | Keeps the chain efficient | After each heavy use |

Tensioning | Prevents wear and keeps the chain tight | Every time you use it |

Lubrication | Reduces friction and wear | Every time you refuel |

Note: Always use high-quality bar oil to ensure smooth operation and prevent overheating.

No matter how well you maintain your chain, it will eventually need replacing. If your chain starts to cut unevenly, burns the wood, or becomes excessively dull despite sharpening, it’s time for a new one. Continuing to use a worn-out chain can damage your saw and compromise safety.

Professionals, such as arborists or loggers, require chains that can withstand the wear and tear of high-volume, high-intensity cutting. They need chains that can cut through tough hardwood, frozen logs, and debris without dulling too quickly. Durability and performance are their top priorities when choosing a chainsaw chain.

For DIY users, safety is paramount. Chains designed for reduced kickback and ease of handling are essential for less experienced users or those who use their chainsaw occasionally. Low kickback chains are ideal for DIY tasks, providing both safety and ease of use.

The right chainsaw chain should balance durability, safety, and cutting efficiency. Whether you're a professional tackling large hardwood trees or a DIY user cutting firewood, choosing the right chain for your needs ensures a safe and productive cutting experience.

Choosing the right chainsaw chain is crucial for effective hardwood cutting. Power alone won’t ensure success. Proper chain selection ensures fast, precise, and safe cuts. By considering factors like cutter profile, chain pitch, and material, you can select the best chain for your needs. ZHEJIANG TRILINK HUIHUANG CO. LTD. offers high-quality chains that deliver superior performance and durability, making your cutting tasks easier and safer.

A: The chainsaw chain is key for efficient, precise cuts. Power alone can't compensate for a poor chain. The right chain ensures durability, reduces kickback, and cuts faster through dense hardwood.

A: Semi-chisel chainsaw chains are ideal for hardwood. They provide a balance between durability and cutting speed, making them perfect for tough hardwood environments.

A: Check your chainsaw's pitch, gauge, and drive link count. These specs must match the chainsaw chain for optimal performance and safety.

A: The chainsaw chain may be too soft for dense hardwood. Chains with sharper teeth, like full chisel chains, cut fast but dull quickly on tough woods, while carbide-tipped chains are more durable.

A: No. Different woods require different chain types. For hardwood, a semi-chisel chainsaw chain is recommended, while softer woods may require a full chisel chain for faster cuts.

A: Replace the chainsaw chain when it no longer sharpens well or causes uneven cuts. Regular maintenance ensures safety and efficient cutting.